Aluminium and other light metals casting: our craft for more than 55 years

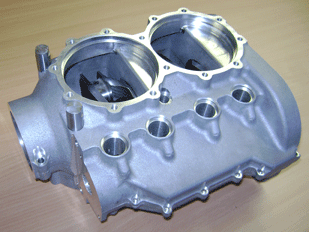

Our aluminium foundry has been producing complex technical parts in sand casting (green or chemical sand), in various alloys of aluminium and other light metals since 1957. Our speciality is the study and production of heavy technical pieces, from 10 to 400+ Kg: carters, converters, casings for transmission or braking systems, and so on. We cast small to medium-sized series, but also your prototypes (and this can go very swiftly!). Sand-casting allows us to make nearly any large part in aluminium; if need be, we can also supply you with die-casted parts.

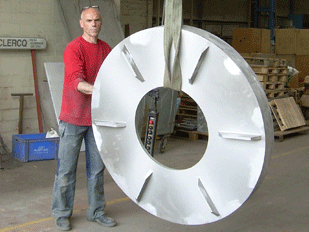

Our main strength is our flexibility: from one to 1000+ parts, from a few kilograms to hundreds, from some centimetres to meters… We are proud of our considerable technical experience and craftsmanship in large, heavy and complex technical parts with high-level technical requirements, and the need of a high degree of precision. We can also take care of the machine-finishing and tooling of your parts.

We have always been faithful to our basic craft: casting for third parties, and have developed a large experience in heavy and intricate technical parts. Our production tool has obviously evolved with the technology of the foundry. You will find a mix of traditional craftsmanship and state of the art technology in our premises.

Our design office is at your disposal, with its capacities in technical CAD and in various engineering domains. We can take care of all your prototyping requirements; we are able to supply you with a first prototype in a matter of days, using the 3D printing technology for producing the moulds.

Our customers include both Belgian and French renowned companies. We work for various sectors of industry: the automobile and aeronautical manufacturing sector, railways, spare parts, machine manufacturing (food, textile, consumer goods...), urban furniture, medical devices, but also artists, designers and architects.